- Placing seeds at a required depth consistently, seed by seed, and row by row, requires proper down force management during planting.

- Excessive down force can cause compaction zones and lower actual seeding depth.

- If too little down force is applied, planting depth can be shallow and seed-to-soil contact may not be adequate.

- For the most consistent and dependable management, an automated down force system should be considered as it can better adjust for field variability.

Planting time is the last opportunity to alter the physical environment in the soil to provide optimal conditions for seed germination and early growth. This is especially critical in no-till situations since it represents the only time the soil will be modified to provide these desired conditions. For optimal conditions, seeds should be placed at a uniform depth, with good seed-to-soil contact, and uniform seed spacing.1

Each crop has an optimum seeding depth that helps foster uniform germination, optimum growth, and maximum yields. The recommended planting depth for corn seed is 1.5 to 2 inches while 1 to 1.5 inches is recommended for soybean seed.2,3 Shallow planted seed is subject to feeding by animals and birds and can result in lodging and rootless corn syndrome. Planting too deep extends time to emergence which can predispose seeds/seedlings to pests and diseases. Consistent seed depth at planting is essential to achieve uniform seedling emergence. Placing seeds at the required depth consistently, seed by seed, and row by row, requires proper down force management during planting. Due to the wide textural variability and different residue conditions in most fields, improper down force management may result in too much down force in some areas and not enough in others.

Effects of Improper Down Force

Firm soil limits penetration by the seed opener, which may make it difficult for the depth wheels to make solid contact with the ground surface. This situation may result in a more shallow planting depth. Excessive down force can cause compaction zones and lower actual seeding depth as well as cause problems later in the growing season as roots attempt to grow into additional soil areas.4

When planting in moist conditions, the amount of down force applied can become problematic. Similar to planting in firm soils, if too much pressure is applied when planting in wet soils, compaction problems may arise that can adversely impact root structure. It is essential to find the right balance of pressure to provide adequate seed-to-soil contact, but without causing over-compaction.5 If too little down force is applied, planting depth can be too shallow and seed-to-soil contact may not be adequate.

Determining Optimum Down Force

Finding the optimum down force to help provide the right soil conditions for seeds can be a challenge. Planting conditions are typically less than ideal across a field, which makes it more difficult to provide ideal conditions for seeds. Practices and technology that provide better soil conditions for the seed can serve to increase agronomic efficiency and yield potential.

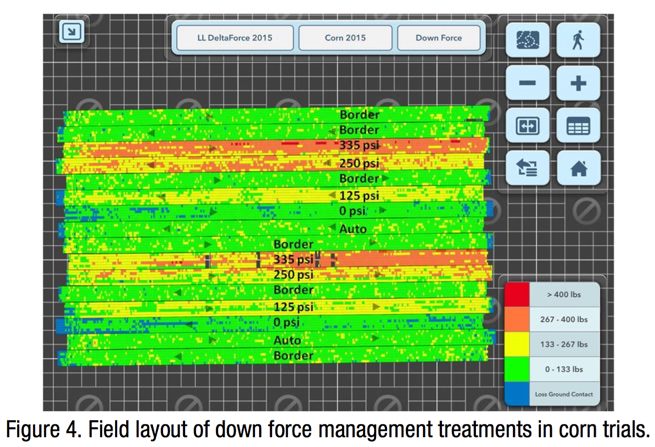

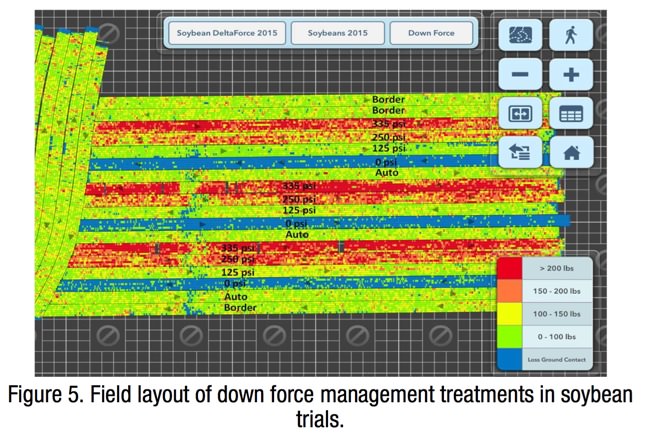

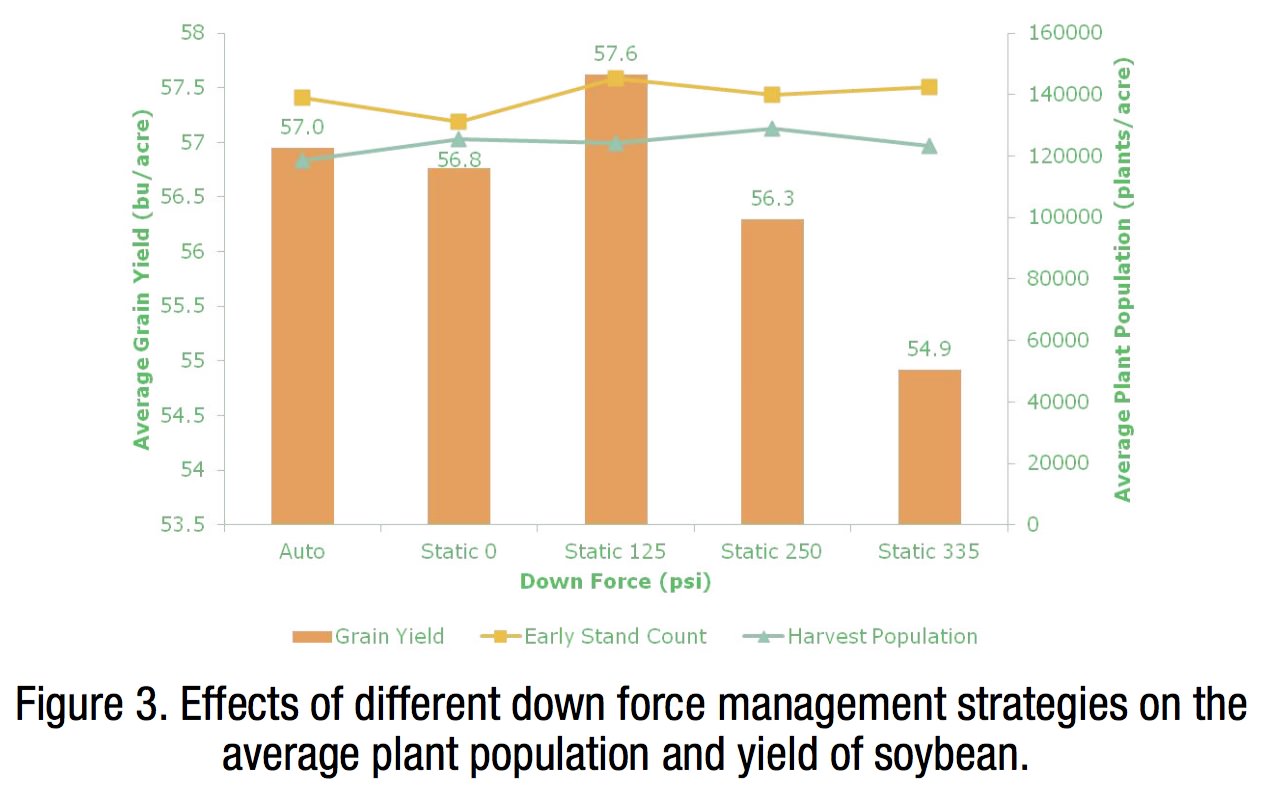

Down force can be manually set with each planting situation, or an automatic down force system can be used. In 2015, the effect of planter down force on yield was studied at the Monsanto Learning Centers at Gothenburg, NE and Huxley, IA. In each study, a range of manual down forces were compared to one another and an automated system. The Gothenburg trial, which examined effects on corn, found that the treatments using 125 lbs or less force or the automated system averaged the highest yields (Figure 1).6 In the Huxley trial, both corn and soybean yields were studied. The corn trial resulted in similar findings as those from Gothenburg, trials using 125 lbs or less force or the automated system averaged the highest yields (Figure 2).7 The soybean trial results were very similar (Figure 3).7 Both trials confirmed that too much down force can negatively affects yield. There was a yield penalty in both corn and soybean for pressures over 125 psi.

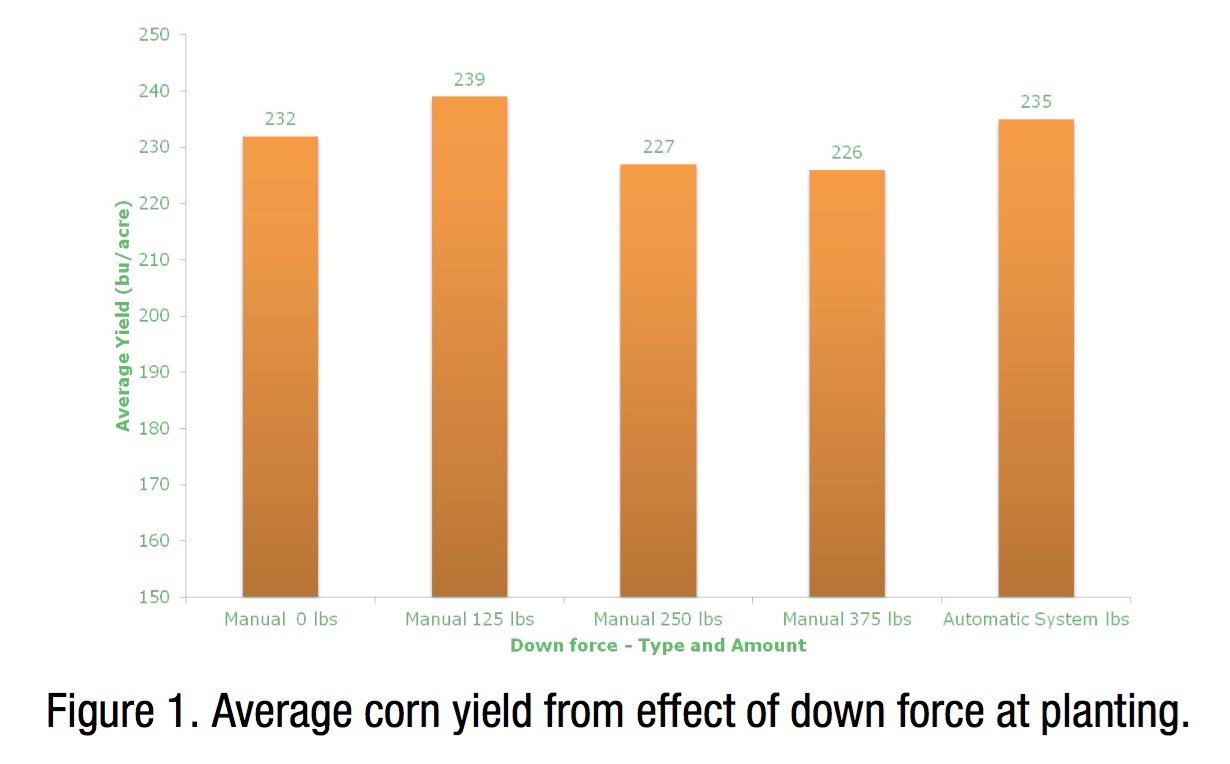

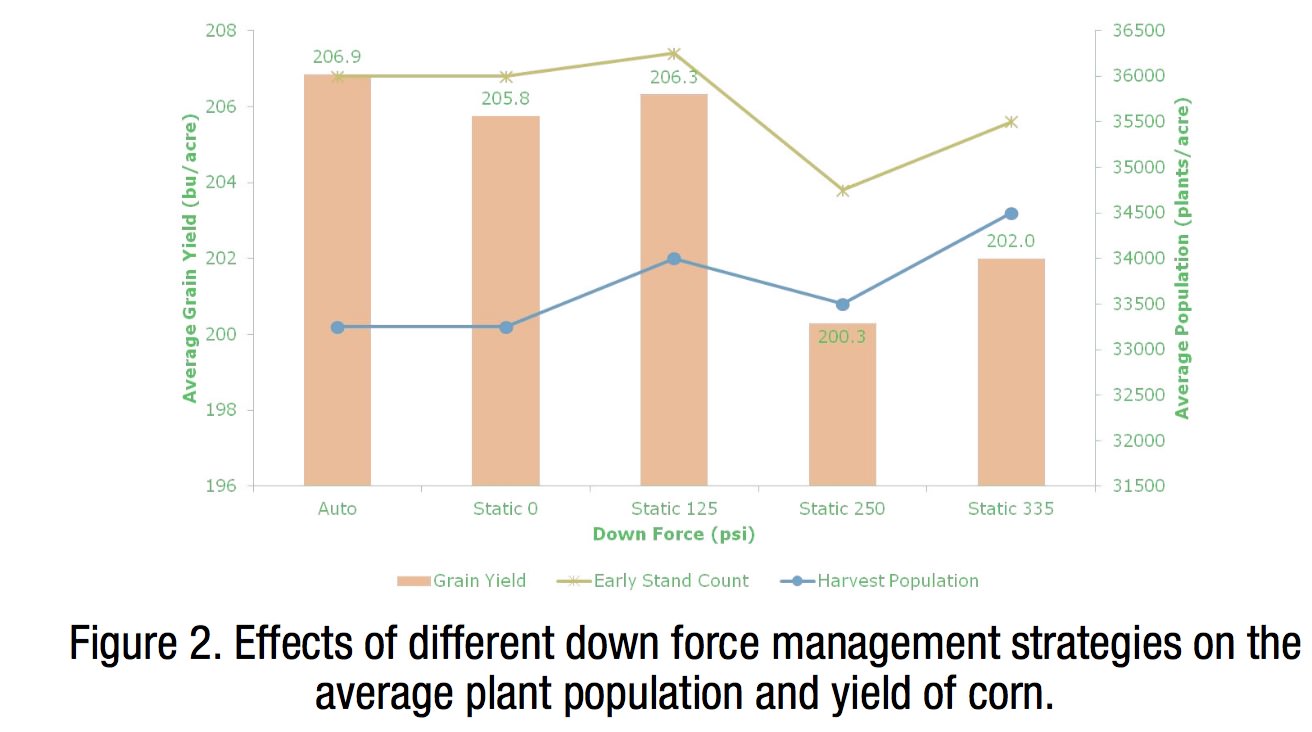

Down force maps (Figures 4 and 5) show how down force was adjusted to meet the requirements of each treatment in the Huxley trial.7 Even though the Static 0 psi produced comparable yields to the Auto and Static 125 psi in both corn and soybean, Figures 4 and 5 reveal how much ground contact was lost in the Static 0 psi treatment in both crops. In large fields, this defect could quickly add up and, if coupled with less than ideal growing conditions, negatively affect yields.

For the most consistent and dependable management, an automated down force system should be considered as this can better adjust for field variability. Working with a trusted equipment dealer, farmers can set the base pressure for Auto mode to fit their field conditions.

Considerations for Setting Down Force

- Using appropriate amounts of down force at planting can improve yields compared to excessive down force.

- Determining the ideal down force for a field can be challenging due to varying soil types, tillage conditions, and soil moisture.

- The benefits of automatic down force systems would likely be more evident in fields where greater variability in soil physical properties are encountered at planting.

- Automated down force mode automatically provides the appropriate pressure for each seed throughout the entire field. It can be especially convenient because once in the cab, down force is one thing the operator has the least amount of control over.

- Consider re-evaluating down force settings after each planting rainout because the level of soil moisture may change the best setting for a field. It is unlikely that one setting would be the best for all conditions.